Changes initiated by customers provide major upside potential for automotive suppliers, but half are unable to increase their margins during the product lifecycle. What are the typical challenges linked to managing changes, and how can suppliers maximize profitability? The recipe for success is change management excellence.

How do you manage change?

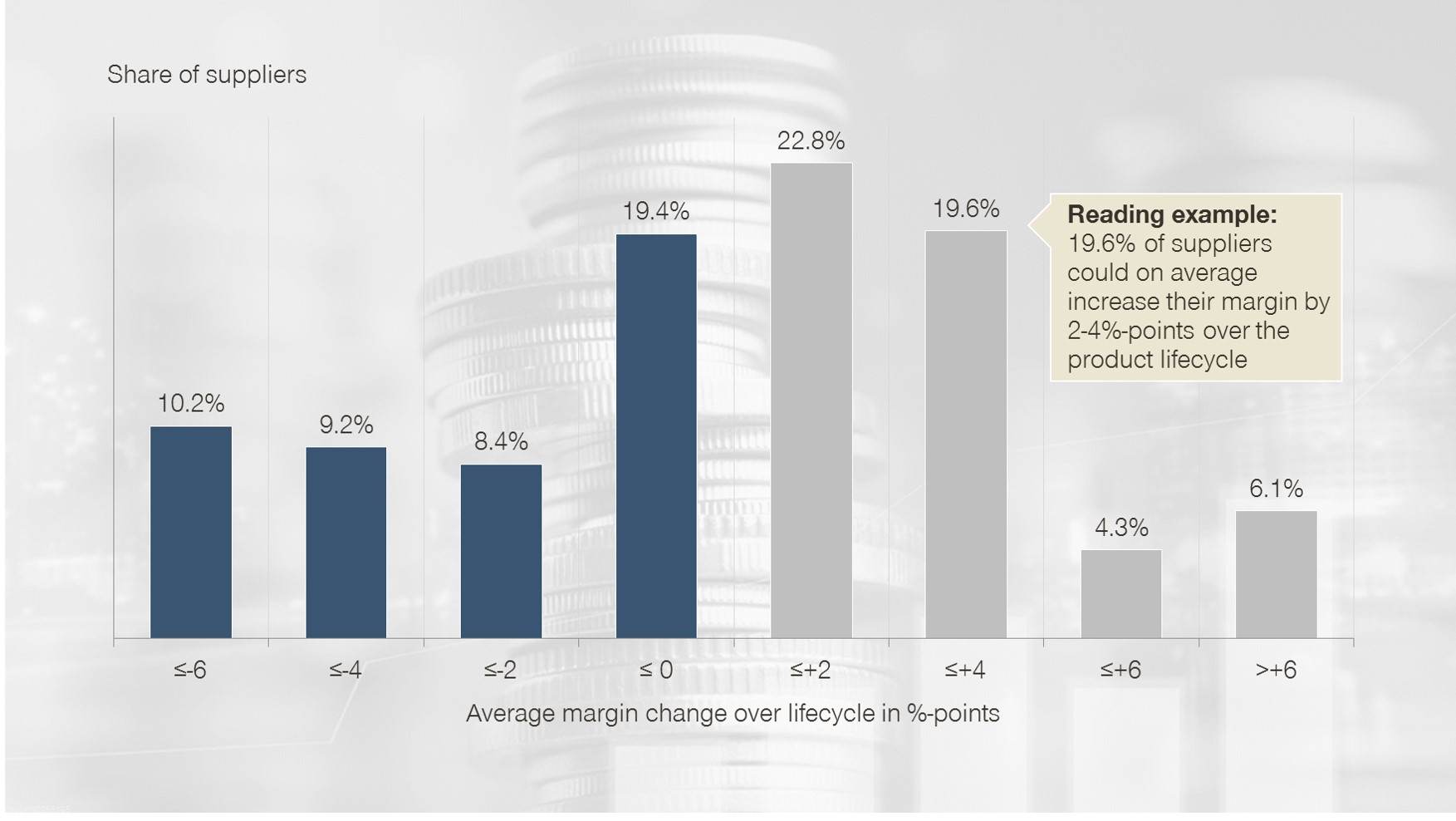

All products undergo changes during their lifecycle. Technical changes, deviations from the agreed volume and variant mix, changing exchange rates, increasing material and energy costs, production transfers – the list is endless. For suppliers, these changes introduced by customers present considerable additional effort that should be remunerated accordingly. In reality, half of suppliers are unable to increase their margins during the product lifecycle, and many sustain margin losses.

A Simon-Kucher study shows there is another way. In a survey on product change management in the automotive industry, the top 10% of suppliers stated that they were able to increase their margins over time by more than 4%-points on average.

Imagine now, that two companies out of these extremes compete with each other: The supplier who loses margin during projects will need to compensate for this when trying to win projects in the first place via higher prices. The company, who can be confident of later increasing the profitability, can offer somewhat lower prices and is much more likely to get nominated for new business and will be able to gain market shares.

Figure 1: Margin changes per supplier during the product lifecycle

Source: Simon-Kucher & Partners Global Pricing Study

In numerous projects with suppliers, we repeatedly observe the same reasons for customers failing to increase margins during the product lifecycle. In many companies, Sales is not informed about all relevant changes, preventing successful monetization. In others, cost changes are communicated to the customer by the technical department in advance, which makes later value argumentation very difficult. Additionally, many of our clients simply lack the time and awareness to actively manage project changes to improve margins. Seldom do we find companies with methods, systems, and processes to systematically implement margin increases across the product lifecycle.

Figure 2: Top mistakes of automotive suppliers in project change management

Source: Simon-Kucher & Partners Project experience

Effective project change management techniques

Simon-Kucher & Partners has supported numerous companies in achieving considerable margin increases through change management excellence. We review and optimize change management in six areas:

- Increase awareness. Not everyone is aware that changes can be used to increase profitability. The first step is to sensitize all technical, logistics and sales employees to this topic and the related opportunities. Management attention here is a key success factor.

- Optimize processes. The process to manage changes along the lifecycle is often not clearly defined. Clear roles, tasks, and responsibilities for all functional areas are needed so that all relevant changes are recorded and systematically negotiated.

- Create infrastructure. Changes often don’t lead to a margin increase, since they are simply not recognized due to a lack of transparency and change monitoring. Equip employees with the necessary data quality and tools to identify, assess, and monitor changes.

- Strengthen contract management. Successful change management starts with project acquisition. In many cases, contract design prevents charging for changes. A clear definition of what is part of the quote, including underlying assumptions, needs to be implemented and then continuously monitored. This will help to negotiate changes later on.

- Improve pricing. Price increases, or more accurately the price quality of changes, can vary even within one type of change, and it often comes down to employee experience. What’s needed is a transparent and market-oriented system that helps the sales force to consistently tap into willingness to pay. This can be a simple checklist with reasons for higher margin expectations (e.g. urgency, risk, negotiation power etc.), or an actual pricing model that delivers situation specific price recommendations.

- Strengthen negotiation conduct. Planned price increases are often heavily reduced during negotiations, with reasons ranging from insufficient negotiation preparation and unrealistic targets to poor negotiation tactics. Here you need to not only enhance your negotiation process, but also your employees' ability to systematically introduce price increases based on customer-initiated changes.

Optimize change management today!

Changes initiated by customers provide an excellent opportunity to increase margins, but companies often fail to seize this opportunity. Weak change management is often to blame. With the right approach, automotive suppliers can achieve increases of up to four percentage points and significantly increase profitability during the product lifecycle.

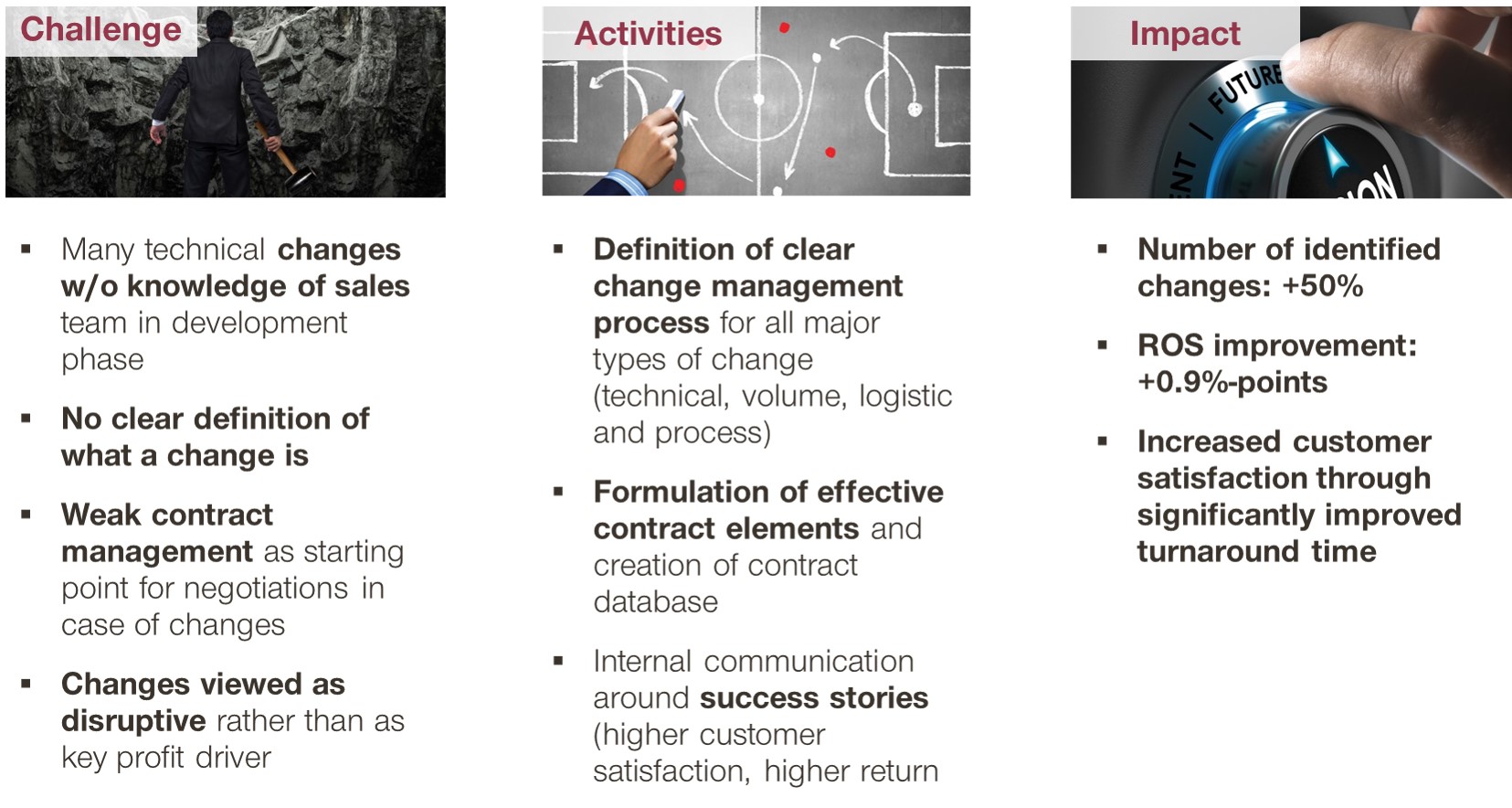

Figure 3: Case Study

Source: Simon-Kucher & Partners Project database